Partnering for Success: Shibaura Machine's Technical Sales Support Services

ELK GROVE VILLAGE, IL, July 20, 2023 - As the manufacturing landscape continues to evolve, having a reliable technical sales support team becomes increasingly important. With inefficiencies in injection molding processes translating into financial losses, it is key to have an expert partner to navigate the industry challenges.

Shibaura Machine's injection molding team is committed to offering comprehensive technical support services designed to assist manufacturers. With Shibaura Machine's technical sales support managers (TSSMs) by your side, you can proactively address inefficiencies, reduce downtime, and optimize operations.

Leveraging Our Experience and Expertise

Our TSSMs bring a wealth of knowledge and experience in injection molding across various industries. With over 86 years of combined injection molding expertise, the team is able to offer insights and advice that enable manufacturers to create efficient processes for their specific needs.

Tailored Solutions for Optimal Results

Our TSSMs work closely with customers in the United States, Canada, and Latin America, providing a range of solutions to optimize injection molding processes. Here are several areas where our technical support services excel:

Machine Size and Specifications

Determining the right machine size and specifications based on your mold and application requirements is crucial for optimal results. For instance, a machine that is too small for a mold will not provide enough clamp force or shot size to fill the cavities, resulting in a poor and inconsistent product. Our TSSMs will guide you through this process, ensuring that your equipment is perfectly aligned with your production needs.

Energy Audits

To improve sustainability and reduce costs, our team can perform energy audits on your injection molding machines. The team can assess the energy efficiency of equipment, identify potential savings, and suggest the most appropriate course of action. This will help you make informed decisions that positively impact your bottom line.

Machine Controller Training

Maximizing overall equipment effectiveness (OEE) is essential for productivity. For instance, our TSSMs can provide training on advanced machine controls to help your team optimize machine performance, reduce production costs, and increase throughput. With in-depth machine controller training your team can leverage the full potential of the injection molding machine and achieve peak performance.

Scientific Molding Techniques

For customers looking to optimize processes, our TSSMs offer expertise in scientific molding techniques. By applying data-driven methodologies, we help you develop efficient and consistent molding processes, minimizing waste and maximizing output.

Mold Processing and Optimization

Introducing different or challenging molds can be overwhelming. Our TSSMs are here to assist you, providing valuable guidance and support throughout the mold processing stage. For example, our TSSMs offer advice on how to optimize processes, troubleshoot any mold issues, and maintain the highest standards of quality assurance. With their expertise, you can overcome obstacles and ensure seamless production.

Machine Set-up and Cycle Time Minimization

Efficient machine set-up and minimizing cycle time are crucial for meeting production targets. Our technical support services include assistance in optimizing machine set-up, enabling you to achieve faster cycle times and increase overall efficiency.

Your Committed Partner in Manufacturing

As the manufacturing industry continues to evolve, Shibaura Machine remains dedicated to helping you achieve your business goals through optimized injection molding processes.

Partner with us today and unlock the true potential of your injection molding operations.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Invest in Your Success: Shibaura Machine's Training Programs for Injection Molding Professionals

ELK GROVE VILLAGE, IL, July 5, 2023 - When it comes to injection molding, having a well-trained team is crucial for maximizing machine performance and achieving optimal results. Training ensures that all personnel understand not only the machine's capabili...

Read moreAchieving Injection Molding Excellence with Integrated Auxiliary Equipment

ELK GROVE VILLAGE, IL, June 21, 2023 - Staying ahead of the competition in manufacturing requires adopting innovative solutions that enhance productivity and efficiency. Auxiliary equipment offers a way to enable precise and automated handling of materials...

Read moreDriving Sustainable Development: The Rise of All-Electric Injection Molding Machines

ELK GROVE VILLAGE, IL, June 7, 2023 - As sustainability becomes an increasingly important focus worldwide, industries are seeking innovative solutions to align their operations with the United Nations' Sustainable Development Goals (SDGs). In the world of ...

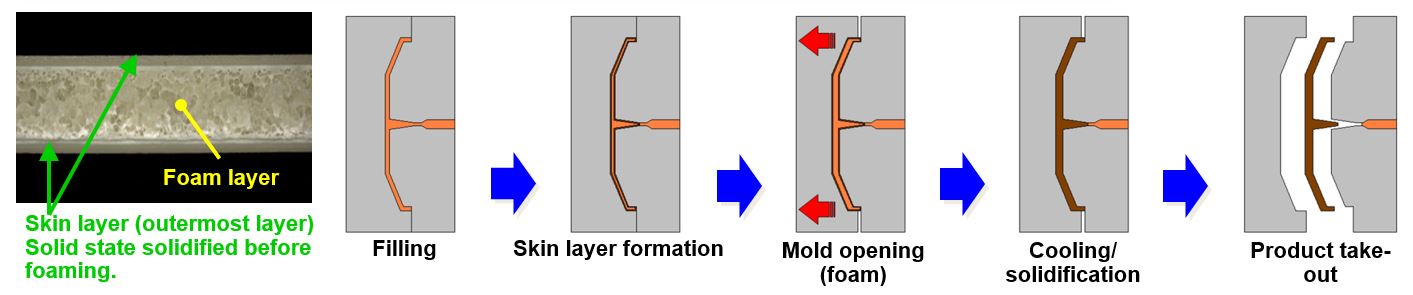

Read moreAchieve Weight Reduction and Precise Control with Core Back Foam Molding

ELK GROVE VILLAGE, IL, May 24, 2023 - Foam molding has emerged as a highly popular and versatile technique in the plastics industry. This method offers a plethora of advantages, ranging from significant part weight reduction and improved shock absorption t...

Read morePrecision Optics and Thin-Wall Molding Made Easier with PRESTROL

ELK GROVE VILLAGE, IL, May 10, 2023 - In order to produce high-quality parts with consistent properties and dimensions, it's important to achieve uniform distribution of material within the mold cavity during the injection process. However, this continues ...

Read moreHow Electric Ejectors Improve Injection Molding Performance

ELK GROVE VILLAGE, IL, November 16, 2022 - An electric ejector system can be a huge competitive differentiator compared to its hydraulic counterparts. The electric ejectors provide molders the ability to view torque giving better insight to allow for impro...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools