Elevating Medical Injection Molding Performance

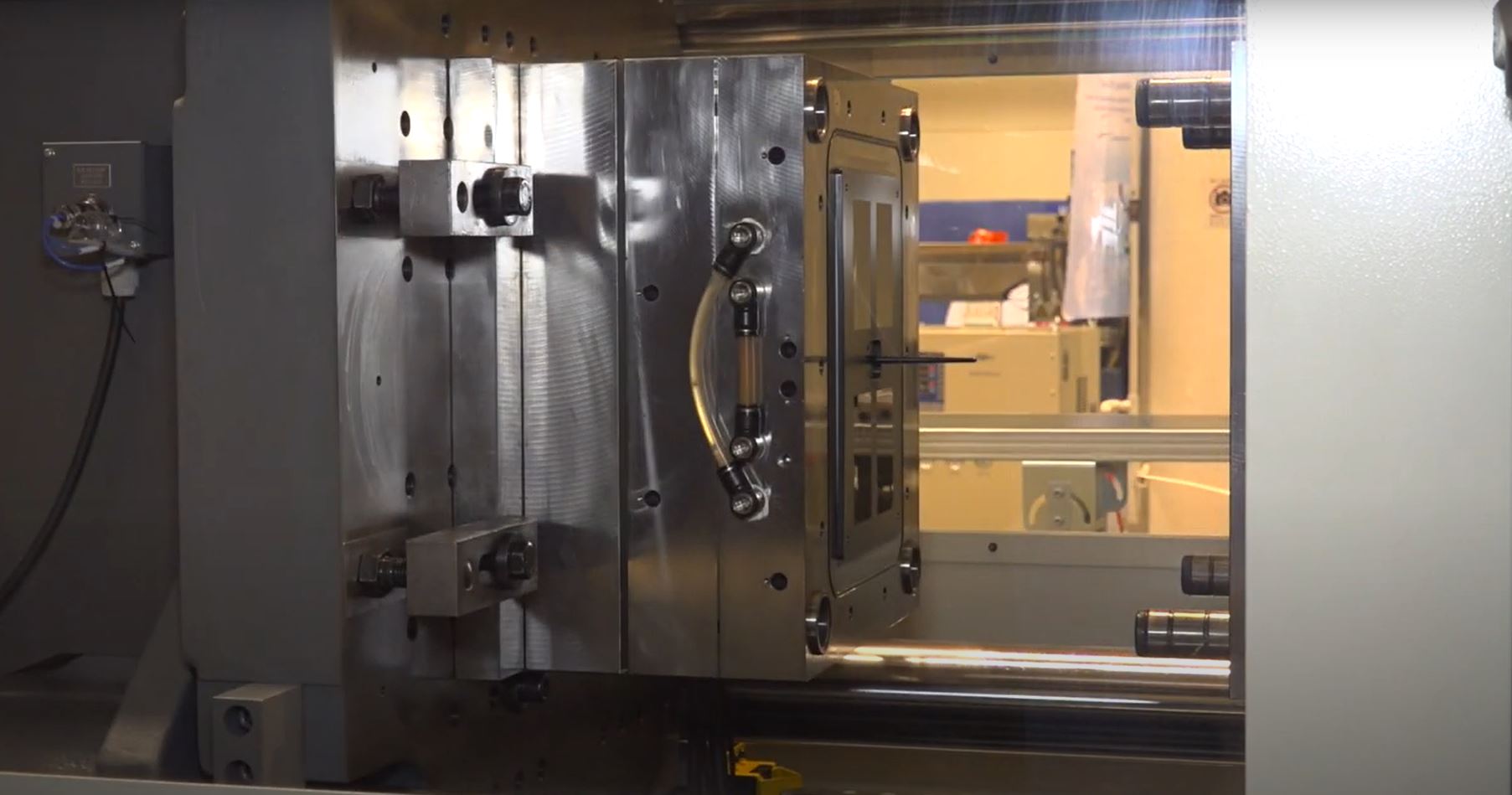

ELK GROVE VILLAGE, IL, February 23, 2024 - A leading provider of precision machinery and manufacturing solutions, Shibaura Machine announced the release of its Medical Spec injection molding machine at the 2024 Plastec West show in Anaheim, CA earlier this month. This latest innovation is set to improve standards in the medical manufacturing industry, where precision, cleanliness, and efficiency are essential.

This machine represents a significant step in modernizing medical component production. It is specifically engineered to meet medical cleanroom standards, ensuring optimal cleanliness and precision. As a testament to our commitment to enhancing medical manufacturing processes' efficiency and quality, the Medical Spec machine marks a new chapter in the industry's growth.

Key Features of the Medical Spec Machine

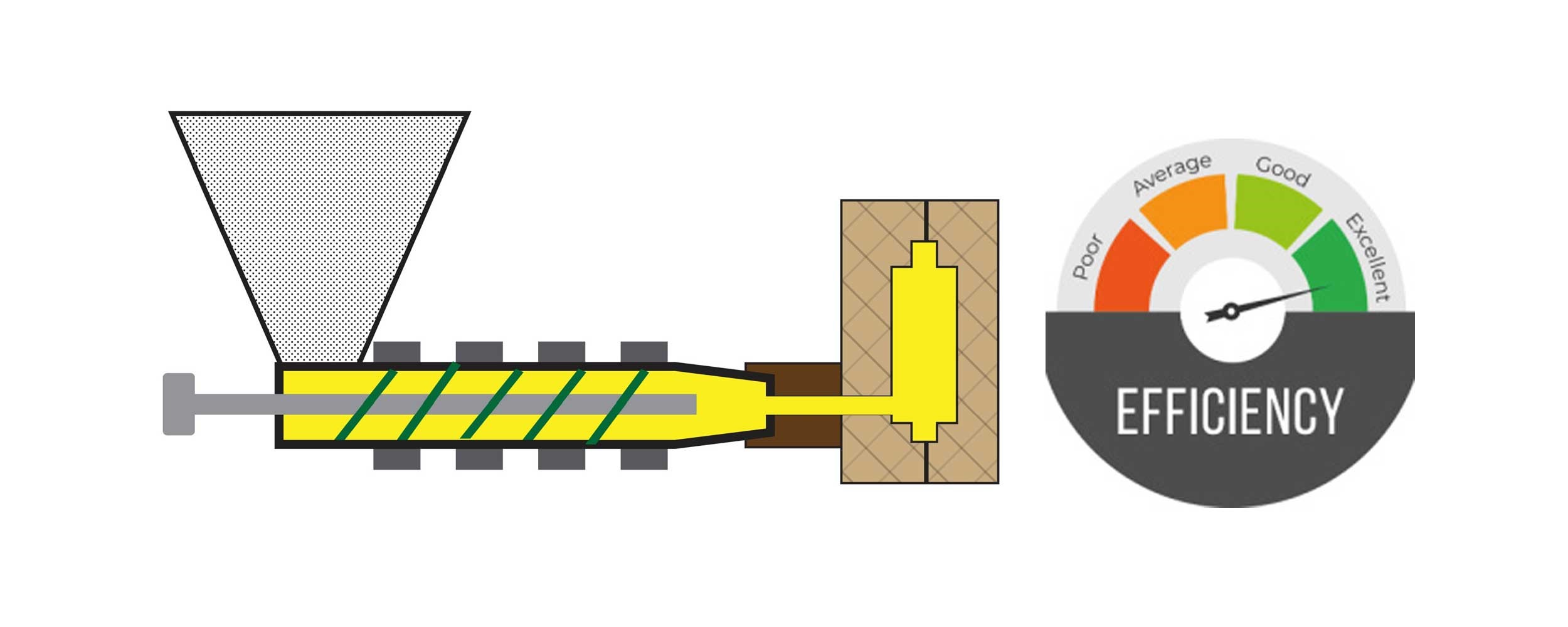

All-Electric for Precision and Energy-Savings:

Delivering exceptional precision in molding with energy-saving benefits, the all-electric machine ensures consistent, repeatable cycles, crucial for medical component manufacturing. Compared to traditional hydraulic machines, the machine significantly reduces energy consumption, leading to cost savings and reduced environmental footprint.

Chrome Plated Platens for Enhanced Durability:

The machine features chrome plated platens, which extend the machine's life and maintain a cleaner environment for sensitive medical production. This plating process reduces corrosion and wear risk, ensuring long-term reliability.

Stainless Steel Guarding and Panels:

Understanding the importance of cleanliness in medical manufacturing, the machine is equipped with stainless steel guards and panels. This choice of material significantly reduces particulate generation, maintaining cleanroom standards.

Raised Platform for Easy Cleaning:

The machine's design includes a raised platform (+100mm), facilitating easy access to clean underneath the machine. This feature is critical to maintaining a contaminant-free environment, ensuring that the production area adheres to the highest cleanliness standards.

Special Lubrication Grease (NFS H1 Certified):

We've incorporated NFS H1 certified special lubricant within our automatic lubrication system. This ensures the machine operates smoothly without compromising the cleanroom environment.

Validated Process Control for Molded Medical Components:

Our machine offers control of validated processes, ensuring each component produced meets stringent medical standards. This includes process parameter control and monitoring, recipe control, shot traceability features, and the integration of Shibaura Machine’s IIoT solution, machiNetCloud.

Machine Performance and Extended Ejector Stroke:

The machine is equipped with an extended ejector stroke (+30mm), increasing its capability to handle a variety of molds and applications. This feature, combined with the machine's overall performance, makes it an ideal choice for producing high-precision medical components.

Modern Medical Manufacturing

Shibaura Machine's Medical Spec machine represents a significant leap forward in medical component production with its advanced features and commitment to cleanliness, precision, and efficiency. Contact the Injection Molding team to learn more.

Tel: (888) 593-1616

Email: im-success@shibaura-machine.com

Related Articles View All Articles

Security and Simplicity: The Dual Focus of the V70 Controller's User Log-in

ELK GROVE VILLAGE, IL, November 15, 2023 - In today's competitive injection molding industry, the difference between leading the pack and falling behind often comes down to the smallest details—like the user log-in experience on your injection molding mach...

Read moreHow Mold Movement During Charging Can Reduce Cycle Times in Injection Molding

ELK GROVE VILLAGE, IL, November 7, 2023 - As the injection molding industry continues to grow at a rapid pace, efficiency is paramount. The capability of simultaneously charging during mold movement has become a game-changing innovation, setting new standa...

Read moreThe Rise of All Electric LSR Injection Molding Machines

ELK GROVE VILLAGE, IL, September 29, 2023 - Are you looking for a way to produce high-quality, intricate silicone components at unprecedented speeds? You're not alone. In a manufacturing landscape where efficiency, versatility, and precision are pivotal, t...

Read moreImprove Your Injection Molding Process with Barrel Temperature Shift Mode

ELK GROVE VILLAGE, IL, August 23, 2023 - To ensure optimal product quality, consistency, and operational efficiency, precise temperature control plays a critical role in the injection molding process. One essential feature that can significantly impact inj...

Read moreMastering Material Changeovers in Injection Molding

ELK GROVE VILLAGE, IL, August 8, 2023 - Optimizing efficiency and minimizing costs are crucial to success in the fast-paced world of injection molding. However, one aspect that often poses difficulties for molders is the purging process. The traditional me...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools